FIBERFLON® is also the name of leadership in manufacturing of high performance process belts. FIBERFLON® industrial conveyor belts combine the non-stick surface and heat resistance of PTFE (polytetrafluoroethylene) and with the strength and dimensional stability of fiberglass. The unique behaviour of these materials results in a product that is more practical and cost-effective than conventional belting materials which is ideal for the demands of many different industrial conveyor applications. Dimensionally stable from -73° to +260°C (-100° to +550°F), FIBERFLON® belts are non-toxic, tasteless odorless, EU food regulations and FDA compliant (21 CFR 177.1550) for use in food contact processing and packaging. In addition, FIBERFLON PTFE belts offer exceptional durability and extremely low elongation (<1%).

| Alligator |

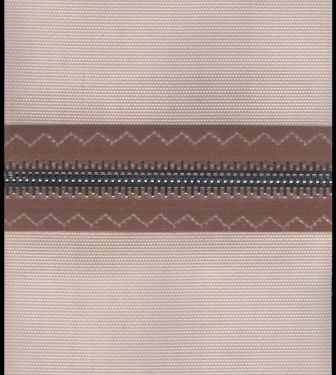

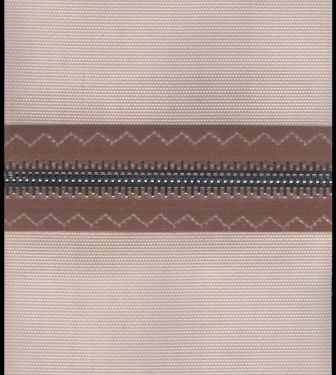

Metal Clipper |

PEEK-Spiral |

|

|

|

| Alligator splices offer exceptionally strong metal lacing. These are recommended for use with 127 mm diameter, or larger pulleys |

Clipper is a metal lacing. This strong and extremely flexible splice conforms well to smaller diameter pulleys. |

Peek-spiral splices are made by hand integrating them in to the end of open mesh belts. This system offers a similar connecting method as our bullnose loop. This joint maybe used or specified in application where wear of the connection may be a problem. If a large metal connection pin needs to be used then this joint is suitable. |

| Bullnose |

Castellated |

Overlap |

|

|

|

| Bullnose splices are made from Kevlar material coated with PTFE resin, featuring high strength and good abrasion resistance. It is widely used on PTFE mesh belt, and occasionally used on PTFE fiberglass conveyor belt. The common mesh size is 4×4mm. |

Castellated Seal splices are flexible and can be reinforced with stitching for extra strength. Use Castellated Seal splices where metal is undesirable |

Overlap splices are the most popular type used in the industry and can be enhanced with molding for food processing applications. Overlap ranges from 25 mm to 152 mm, with directional belt angles of 30, 45, 60, and 90 degrees, |